Kettles are generally more costly than other reboiler types due to shell size surge volume size and uncertainty in the TMTD. Kettle reboiler design calculation Produce fascinating 3D nail artwork designs with 3D Nail Art Jewelry with the Nail Superstore.

Kettle Reboiler Sizing Process Heat Transfer Cheresources Com Community

P pd pe pr 2H2 1H1.

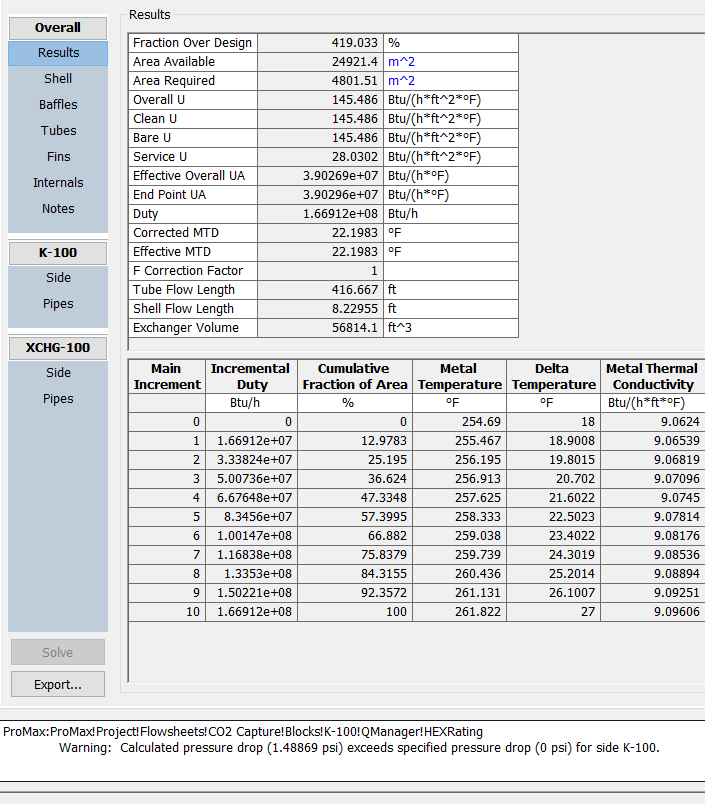

. The tube length for straight tubes is taken as the actual overall length. The software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial. Have traditionally been used for the design of commercial kettle reboilers.

Note that the liquid circuit between the column base and the thermosyphon reboiler forms a U tube. Installations include column bottom reboilers side reboilers or vaporizers. Perform thermal design calculations and analysis of Kettle type reboilers as well as preliminary sizing calculations.

This problem can be more severe in horizontal thermosyphon reboilers where the percent vaporization is higher. 8 - 21 PLANT DESIGN - Daniel R. A method has been worked out to easily estimate the possibility and severity of entrainment and hence determine proper shell diameter of kettle-type reboilers.

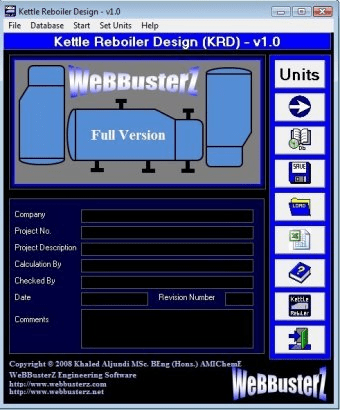

This software product will do thermal design calculations and sizing for this type of heat exchangers. Trapping the liquid from the first tray then becomes essential for this type of reboiler to function. P 1 288 1h1 2h2 friction losses.

42132 Nominal Length The nominal length is the tube length in inches. Lewin Reboiler Circuit Design Example Calculation Downcomer. I Or Q req H out - H in M in Q liq.

GDOT 2001 STANDARD SPECIFICATION BOOK PDF. Kettle Reboiler design This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilers. Than 40 of the kettle shell diameter.

They are often used as vaporizers as a separate vapor-liquid disengagement. For kettle reboilers and chillers that have a narrow end and a fat end the nominal diameter is the port narrow end followed by the shell diameter each rounded to the nearest integer. List of the main features.

Once-through Reboiler DesignNatural circulation is maintained if P driving force p frictional losses Driving force for circulation. Kettle Reboiler Design 30. For practical reasons better separations of entrainment liquid level at.

Kettle Reboiler Design 31 can be downloaded from our software library for free. Kettle reboiler is also called a submerged bundle reboiler. Kettle Reboiler Heat Exchanger Software Features KRD Different units of measurement SI units and English US units a unit converter that includes 23 measurements units with 200-unit conversion is also included with this product.

0QRQCFHfDHdBFb where QR reboiler duty QC condenser duty Hf enthalpy of feed etc and get the signs right for streams and energy entering or leaving the process. P1 P2 P 1 144 1H1 2H2 Pi pressure psi i density lbft3 H1 head ft Introducing a safety factor of 2. Such as that of 37900 Wm 212000 Btuft h recommended by Kern 1950.

KettleReboilerexe and Kettle_Reboiler_Designexe are the most frequent filenames for this programs installer. P 1 288 1H1 2H2 Friction Losses. Kettle Reboiler design KRD Software Features.

Calculation of Duty Area Tube length. The heating fluid is inside the tyle. Considered one of the most well-liked nail art enhancements unfortunately 3D nail art will also be The most time consuming to carry out.

Kettle Reboiler Design free download. P1 p2 p 1 144 1h1 2h2 pi pressure psi i density lbft3 h1 head ft introducing a safety factor of 2. This tool was originally designed by WeBBusterZ Engineering Software.

56100 lbhr ρ V 132 lbft3 2 3 100 70 307 30 132 406 lbft ρ 8 - 22 PLANT DESIGN - Daniel R. To minimize liquid entrainment in the exit vapor is the main difficulty in the design of the reboiler. P pd pe pr 2h2 1h1 pe reboiler p psi usually 025-05 psi pd downcomer p psi pd pr 01-1 psi100 ft by design pr riser p psi 8 - 14 plant design - daniel r.

Calculate the heat-transfer coefficient and heat-transfer rate section-by-section up the tubes. H for reboilers is often in between 75 to 750 kcalhm 2 c 0087 to 087 kWm 2 K. Calculate the rate of vaporization from the total heat-transfer rate and compare with the value assumed in step 1.

This has had important implications in the application of submerged bundle reboilers as the high heat flux allows a smaller bundle to be used which can then often be installed in the base of the column. H overall heat exchange coefficient kWm 2 K S area of the heat exchanger m 2 ΔT ml K The value of S can thus be calculated as a 1st approximation of the heat exchanger size. Such as Chens method.

The software has many features to read more about these features please visit webbusterz. Calculation of the vapor rate G which is released in flashing the heated circulated liquid F. Multiplying the difference in specific enthalpy of outlet vapour and reboiler inlet liquid by the outlet vapour mass flow rate Q req H out - H in M in H liq H in M liq.

Use a suitable method for the sections in which the boiling is occurring. Now to the reboiler duty. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilersThe software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

These reboilers are widely used in the chemical and refining industries. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilersThe software is user friendly and can be used to make preliminary sizing calculations that. Ability to use to different units of measurement SI.

Lewin Reboiler Circuit Design Example Calculation. It is assumed that the degree of sub-cooling and super-heating of the cold fluid is negligible i. 186850 lbhr ρ 1 367 lbft3 Riser.

The freeboard between the liquid level and shell should be at least H 1 9. Below is a list of the main features. 130750 lbhr ρ L 367 lbft3 vapor.

For kettle reboilers and chillers that have a narrow end and a fat end the nominal diameter is the port narrow end followed by the shell diameter each rounded to the nearest integer. Kettle type reboiler is a type of shell and tube heat exchanger with differences in design basis some of which are as follows. This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilersThe software is user friendly and can be used to make preliminary sizing calculations that will help to give a clear outlook of the initial design.

The program lies within Office Tools more precisely Calculators. Kettle Reboiler Design KRD v10 Advertisement This software tool is made to demonstrate the thermal design calculations and analysis of Kettle type reboilersThe software is user friendly and can be used to make preliminary sizing calculations that will. F circulating rate 10000.

Download Kettle Reboiler Design 2 0 0

Kettle Reboiler Design 1 0 Download Free Trial Kettlereboiler Exe

Download Kettle Reboiler Design 2 0 0

Kettle Reboiler Characteristics Download Table

Kettle Reboiler Design Version 3 0 Youtube

Reboiler With Circulation Pump Process Heat Transfer Cheresources Com Community

Kettle Reboiler Sizing Software Simple Method To Size A Kettle Reboiler

0 comments

Post a Comment